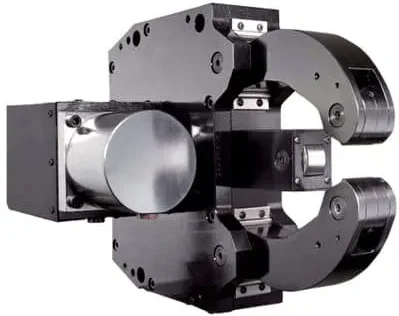

Developed for all standard applications. The FRU steady rests can be mounted to flat or slant bed lathes.

FRU steady rests are used for all standard applications. This series of steady rests are available with clamp ranges from 4 mm to 800 mm. FRU steady rests can be mounted to flat or slant bed lathes. Mounting brackets can be supplied to meet your needs. All Kitagawa-NorthTech steady rest models come with a spare set of rollers and spare chip guard.

STANDARD FEATURES

- Safety valve

- Provision for max. opening feedback

- Spare set of chip guards

- Spare set of rollers

- Provision for compressed air connection

- Provision for centralized lubrication

(Click image for larger view)

| Steady Rest Type | FRU1 | FRU2J | FRU3J | FRU3.1J | FRU3.2J | FRU4J | FRU5 | FRU5.1 | FRU6 | FRU7 | FRU8 | |

| A | 212 | 298 | 462 | 470 | 486 | 624 | 706 | 731.5 | 980 | 1235.5 | 1404 | |

| B | 137 | 195 | 308 | 316 | 332 | 437 | 500 | 520 | 709 | 898 | 1000 | |

| C | 51 | 70 | 115 | 123 | 138 | 146 | 178 | 198 | 215 | 320 | 375 | |

| D | 64 | 85 | 135 | 135 | 135 | 240 | 270 | 270 | 330 | 440 | 500 | |

| E | 118 | 170 | 262 | 262 | 262 | 365 | 400 | 400 | 610/640 | 650 | 855 | |

| F | 132 | 205 | 290 | 290 | 290 | 400 | 450 | 450 | 680 | 720 | 930 | |

| G | 55 | 70 | 85 | 85 | 85 | 110 | 145 | 145 | 145 | 162 | 190 | |

| I | —- | 33 | 37 | 37 | 37 | 37 | 37 | 37 | 46 | 60 | 60 | |

| J | 33 | 42 | 52 | 52 | 52 | 67 | 83 | 83 | 83 | 94 | 110 | |

| K | 25 | 35 | 45 | 45 | 45 | 60 | 75 | 75 | 75 | 82 | 100 | |

| L | 12 | 19 | 25 | 25 | 25 | 25 | 29 | 29 | 29 | 32 | 32 | |

| M | 19 | 35 | 47 | 47 | 47 | 52 | 62 | 62 | 80 | 100 | 100 | |

| N | 10 | 21 | 25 | 25 | 25 | 32 | 40 | 40 | 43 | 55 | 60 | |

| O | 75 | 103.5 | 154 | 154 | 154 | 187 | 206.5 | 211.5 | 271 | 337.5 | 385.5 | |

| P1 | 82.5 | 105 | 137 | 137 | 137 | 165 | 165 | 165 | 190 | 238 | 238 | |

| P2 | 27.5 | 66 | 92 | 90 | 90 | 102 | 102 | 102 | 115 | 143 | 143 | |

| P3 | 55 | 75 | 92 | 94 | 94 | 110 | 110 | 110 | 130 | 158 | 158 | |

| P4 | 118.5 | 188 | 279 | 279 | 323 | 415 | 473 | 509.5 | 732 | 869.5 | 976 | |

| R | 50.5 | 75 | 117.3 | 124 | 139 | 172 | 209 | 236 | 290 | 390 | 402 | |

| S | 11 | 14 | 18 | 18 | 18 | 23 | 23 | 23 | 27 | 27 | 35 | |

| T | 55 | 68 | 102 | 102 | 102 | 126 | 144 | 144 | 158 | 190 | 190 | |

| V | 37 | 60 | 91.5 | 99.5 | 109.5 | 128 | 160 | 180 | 182 | 292.5 | 295.5 | |

| Y | —- | 19 | 19 | 19 | 19 | 19 | 20 | 20 | 27 | 27 | 27 | |

| Centering range without chip guard | U1 | 4 | 8 | 12 | 20 | 50 | 30 | 45 | 85 | 125 | 200 | 230 |

| U2 | 64 | 101 | 152 | 165 | 200 | 245 | 310 | 350 | 460 | 530 | 630 | |

| Centering range with 3 piece chip guard | U1 | 4 | 16 | 16 | 20 | 50 | 30 | 45 | 85 | 125 | 191 | 230 |

| U2 | 64 | 101 | 152 | 165 | 200 | 245 | 310 | 350 | 460 | 530 | 630 | |

| Cylinder bore | d (dia) | 30 | 50 | 80 | 80 | 80 | 100 | 100 | 100 | 130 | 150 | 150 |

| Hydraulic connection (BSP) | h | 1/4″ | 1/4″ | 1/4″ | 1/4″ | 1/4″ | 3/8″ | 3/8″ | 3/8″ | 3/8″ | 3/8″ | 3/8″ |

| Operating pressure min(max) | bar | 6(50) | 8(60) | 8(60) | 8(60) | 8(60) | 8(60) | 8(80) | 8(80) | 8(70) | 6(70) | 6(70) |

| Max clamp force/roller | daN | 100 | 350 | 1000 | 1000 | 1000 | 1500 | 2000 | 2000 | 3000 | 4000 | 4000 |

| Clamping pressure/roller at 15 bar | daN | 35 | 100 | 250 | 250 | 500 | 500 | 500 | 500 | 670 | 900 | 900 |

| Centering accuracy over entire clamping range | mm | 0.02 | 0.02 | 0.04 | 0.04 | 0.04 | 0.05 | 0.06 | 0.06 | 0.06 | 0.08 | 0.08 |

| Repeatability | mm | 0.005 | 0.005 | 0.007 | 0.007 | 0.007 | 0.007 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 |

| Max peripheral speed | m/min | 850 | 950 | 800 | 800 | 725 | 725 | 670 | 670 | 525 | 570 | 570 |

| Approx weight | kg | 7 | 18.5 | 48 | 48 | 50 | 104 | 155 | 155 | 430 | 520 | 580 |