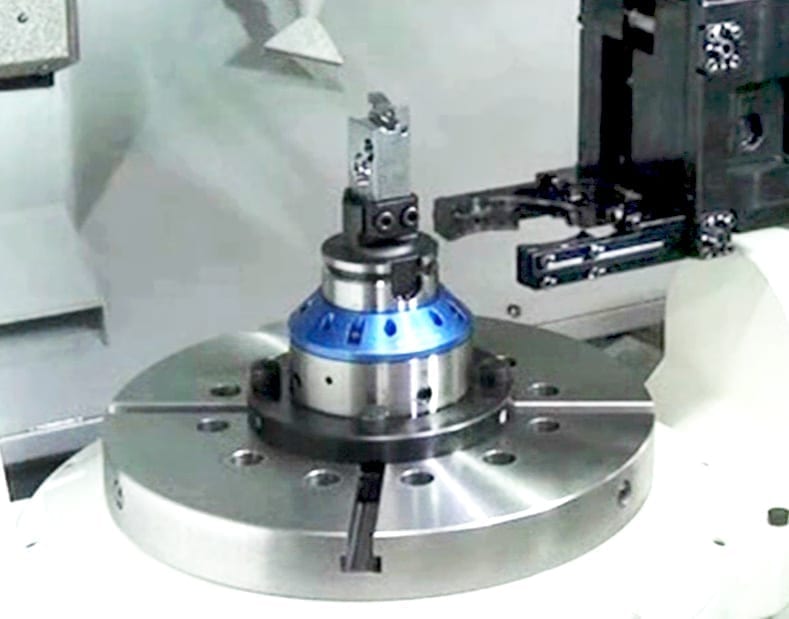

Systems Overview

Maximize the Performance of your 5-Axis Machining Center with Rigid & High Accuracy Work-Piece Clamping Systems

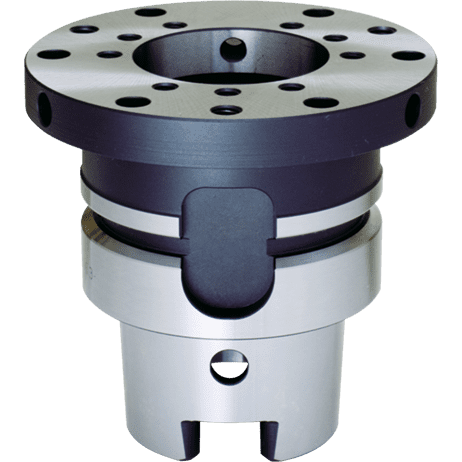

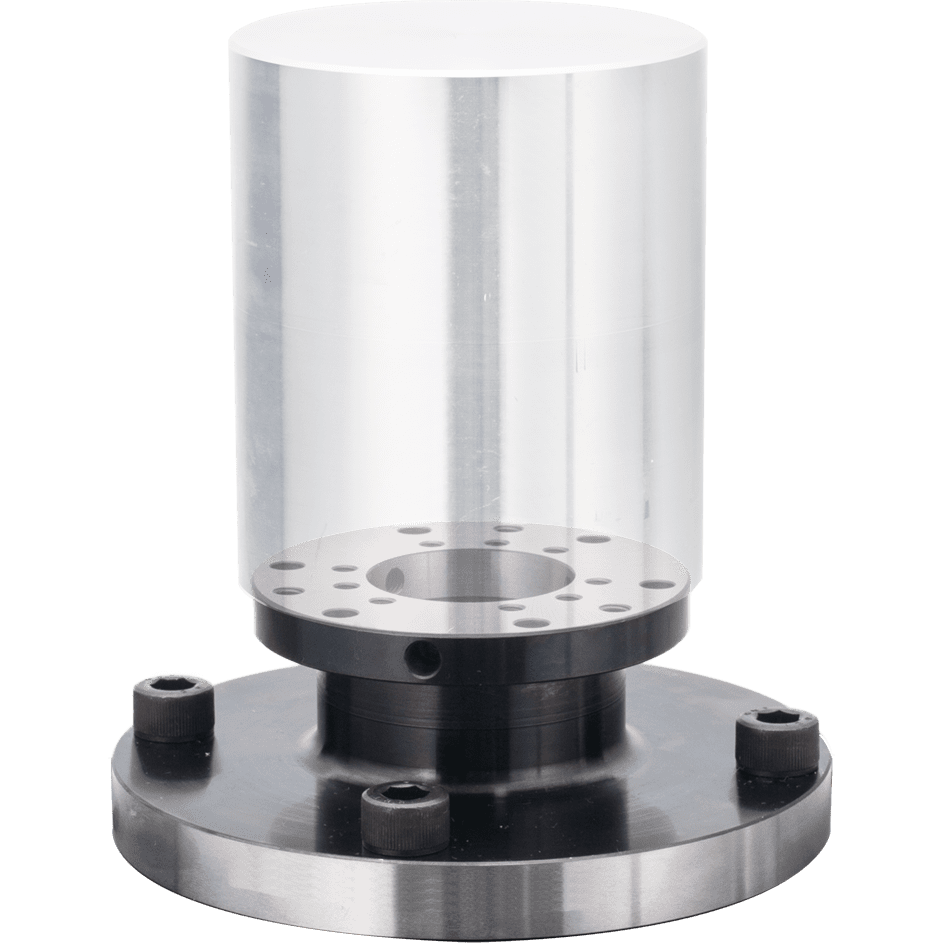

The HSK interface (between the head and the work-holder) and the dovetail clamping (between the work-holder and the work-piece) create a compact design with less interference and high rigidity for metalworking applications

• The rigid system developed for metalworking applications.

• No interference and superior accessibility.

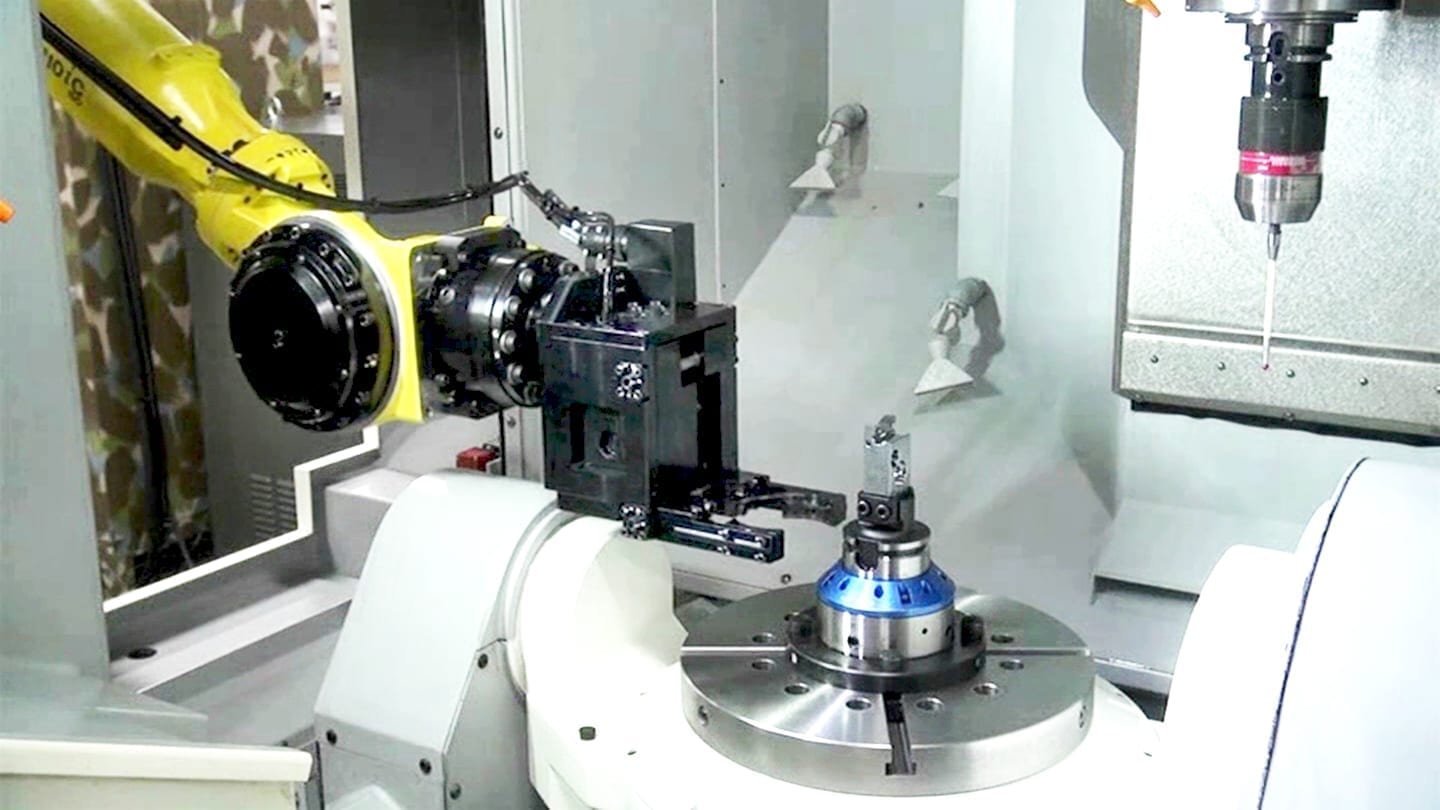

• Handling the work-piece is easy using a general-purpose robot.

2-Face Clamping Work-Piece

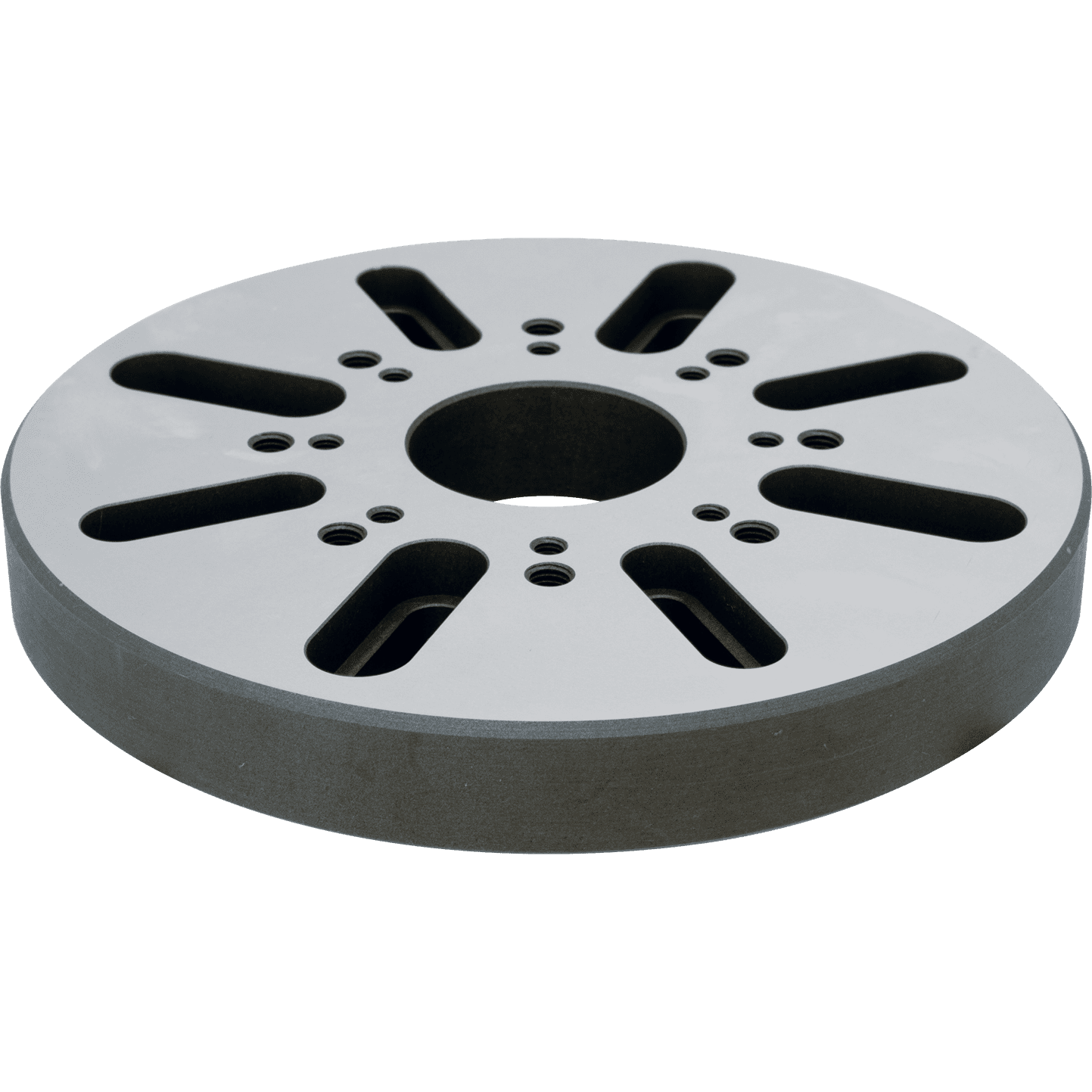

Dovetail Clamping Work-Holder

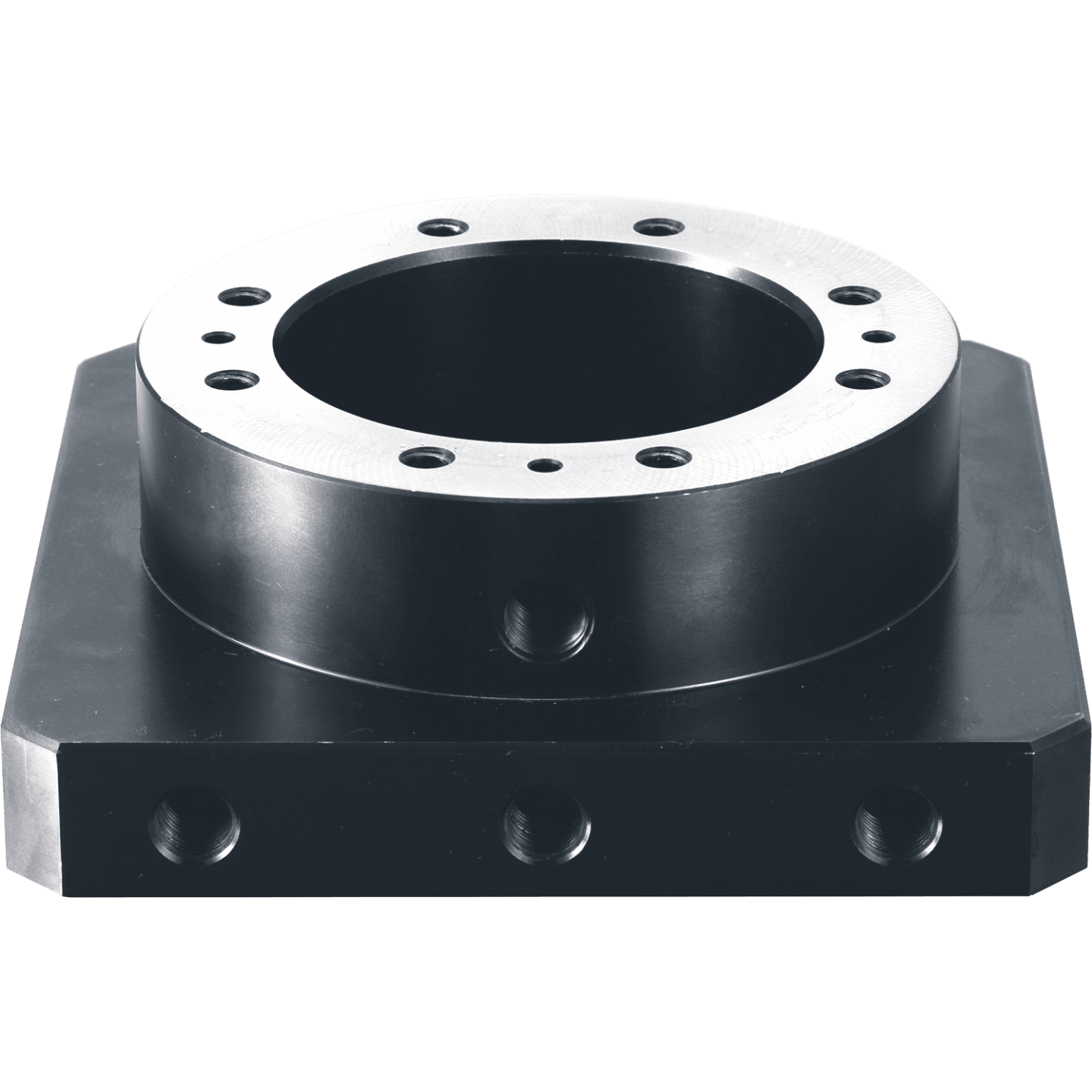

HSK Interface Head

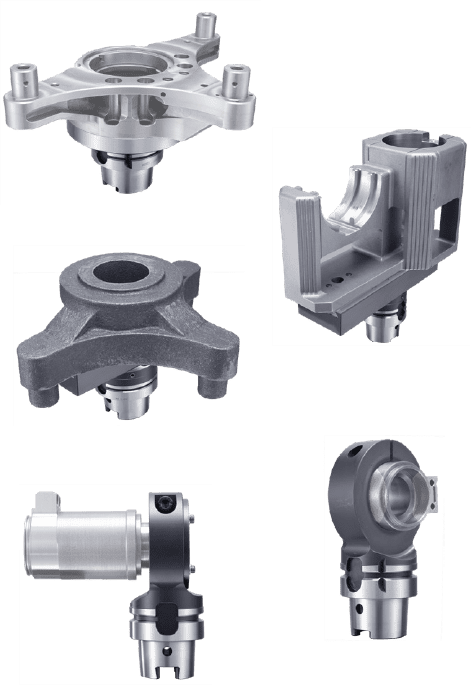

Supports Various Work-Piece Shapes

Work-Piece Clamping & Mounting Options

Direct Clamping

Dovetail Clamping

Flange Clamping

Work-Piece Options

Dovetail

(max. ≤ 200mm)

Large Diameters

(max. 200mm)

Rectangular

(max.depth 30mm)

Square

(max. 40mm)

Small diameters

(max. 25mm)

Workholder Options

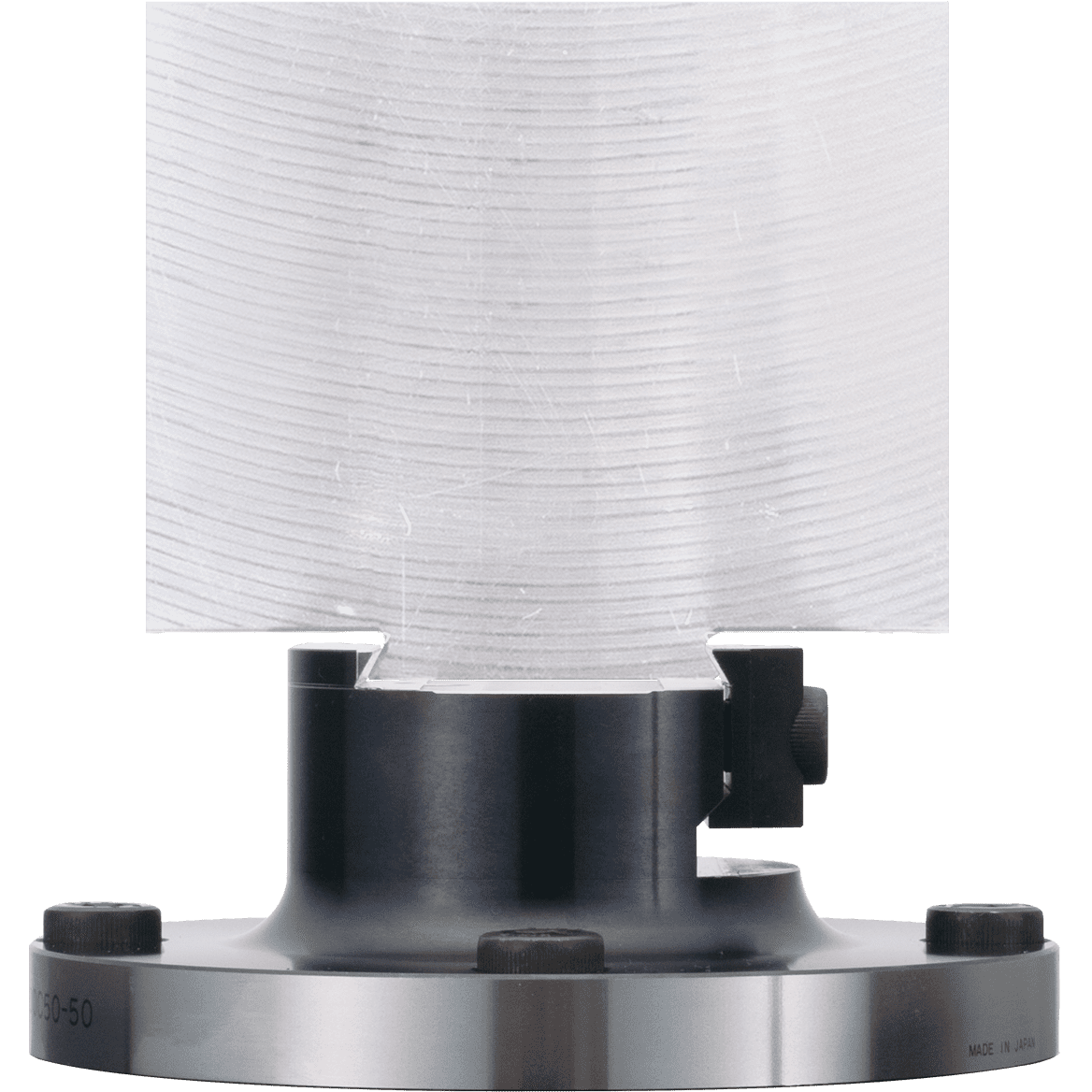

Quick Work-Piece Changing (Manual Clamping Head)

Off-line setup in advance allows quick work-piece changing, minimizing machine downtime.

High Positioning Accuracy

- HSK-A40

- HSK-A63

- HSK-A100

Offsetting the work-piece position in the rotating direction using a touch probe

• Measuring two locations along the work-piece side face using a touch probe enables you to offset the machine table angle easily.

BLUM high accuracy touch probe

For Automation (Hydraulic Automatic Clamping Head)

The hydraulic clamping design allows for automated work-piece changing, and makes it possible for you to combine your machining centers with robots to create a fully-automated system.