The AJPS from Kitagawa Delivers High Precision Workholding Ideal for flexible

High Mix, Low-to-Moderate Volume Machining

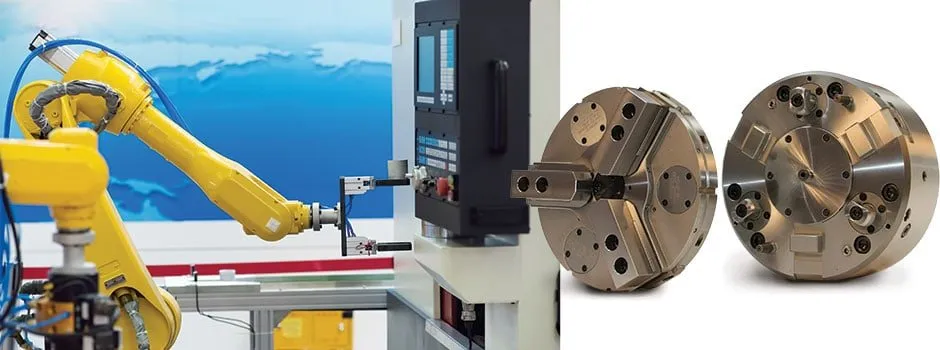

Schaumburg, IL – December 1, 2016 – Kitagawa North-Tech, Inc. introduces the Automated Jaw Pallet System (AJPS) for Robot tended CNC Mill/Turning cells utilized in flexible automated production environments. The AJPS in conjunction with Kitagawa Promano Grippers provide seamless flexibility in a Robot tended machining environment by automating the Workholding and Part Holding change-over allowing the cell to run many different parts in low volumes consecutively, congruently and un-attended.

The Automated Jaw Pallet System from Kitagawa Redefines the Viability of Using Automated Workholding in Low-to-Moderate Parts Volume CNC Machining Operations

The Automated Jaw Pallet System breaks the financial barriers and preconceived notions associated with implementing robotic automation and automated Workholding in CNC machining and parts production operations. Up until now, deploying automation in machine shops was considered only financially viable in high volume; low-parts mix automated CNC machining scenarios. With Kitagawa’s new Automated Jaw Pallet System and Promano Grippers even machine shops with low-to-moderate volume parts production can now affordably deploy Kitagawa’s AJPS solution with robotic automation in their machining operations. AJPS is used to run multiple jobs consecutively overnight, from one to another for maximum productivity, efficiency and profits in machine shops. AJPS offers many other design advantages and unique capabilities including:

- Jaw Pallets that are designed to maintain very close tolerance between changes allowing high accuracy and repeatability of both locating and gripping geometries.

- Pallets are equipped with special Jaws and dust covers designed to prevent any contaminants from intrusion and can be supplied with part specific engineered workholding solutions.

- Kitagawa can also provide the Promano Gripper fingers for your part and pallet geometries as needed.

Media Contact:

DYNAMIC MARKETING ENTERPRISES LLC

David G. Martorana

Dynmarketing.com

Marketing, Communications & Public Relations

1-847-630-6487