STANDARD FEATURES

- Safety valve

- Provision for max. opening feedback

- Spare set of chip guards

- Spare set of rollers

- Provision for compressed air connection

- Provision for centralized lubrication

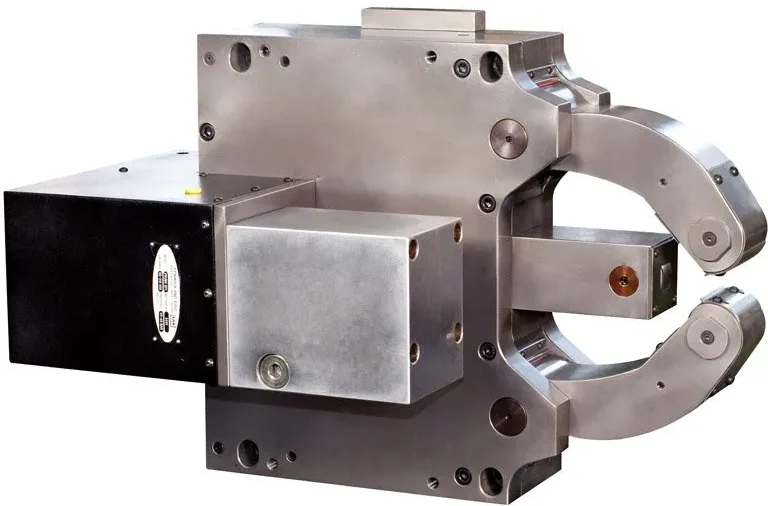

(Click on image for larger view)

| Steady Rest Type | FRUB 3 | FRUB3.1 | FRUB 4 | FRUB 5 | FRUB 6 | FRUB 7 | FRUB 8 | |

| A | 348 | 356 | 480 | 612.5 | 823 | 1001 | 1130 | |

| B | 308 | 316 | 437 | 500 | 709 | 897.5 | 1019 | |

| C | 115 | 123 | 146 | 178 | 215 | 320 | 375 | |

| D | 135 | 135 | 240 | 270 | 330 | 440 | 500 | |

| E | 262 | 262 | 365 | 400 | 610/640 | 650 | 855 | |

| F | 290 | 290 | 400 | 450 | 680 | 710 | 930 | |

| G | 85 | 85 | 110 | 145 | 145 | 180 | 190 | |

| J | 52 | 52 | 67 | 80 | 83 | 112 | 110 | |

| K | 45 | 45 | 60 | 75 | 75 | 100 | 100 | |

| L | 25 | 25 | 25 | 29 | 29 | 32 | 32 | |

| M | 47 | 47 | 52 | 62 | 80 | 100 | 100 | |

| N | 25 | 25 | 32 | 36 | 43 | 55 | 60 | |

| O | 40 | 40 | 43 | 112.5 | 114 | 103.5 | 111 | |

| P2 | 74 | 74 | 85 | 85 | 125.8 | 130 | 130 | |

| P3 | 57 | 57 | 68 | 85 | 89.2 | 130 | 130 | |

| R | 117.5 | 124 | 172 | 209 | 290 | 398 | 402 | |

| S | 18 | 18 | 23 | 23 | 27 | 27 | 35 | |

| T | 199 | 198 | 246 | 325 | 383 | 405 | 487 | |

| V | 91.5 | 99.5 | 128 | 160 | 182 | 283.5 | 290 | |

| Y | 19 | 19 | 19 | 20 | 27 | 27 | 27 | |

| Centering range without chip guard | U1 | 12 | 20 | 30 | 50 | 125 | 200 | 230 |

| U2 | 152 | 165 | 245 | 310 | 460 | 530 | 630 | |

| Centering range with 3 piece chip guard | U1 | 21 | 20 | 30 | 50 | 125 | 200 | 230 |

| U2 | 152 | 165 | 245 | 310 | 460 | 530 | 630 | |

| Cylinder bore | d (dia) | 80 | 80 | 100 | 100 | 130 | 150 | 150 |

| e | 58 | 58 | 68 | 85 | 55 | 191 | 191 | |

| f | 27 | 27 | 39 | 40 | 50 | 50 | 50 | |

| g | 180 | 180 | 220 | 270 | 430 | 450 | 450 | |

| Hydraulic connection (BSP) | h | 1/4″ | 1/4″ | 3/8″ | 3/8″ | 3/8″ | 3/8″ | 3/8″ |

| Operating pressure min(max) | bar | 8(60) | 8(60) | 8(60) | 8(80) | 8(70) | 8(70) | 8(70) |

| Max clamp force/roller | daN | 1000 | 1000 | 1500 | 2000 | 3000 | 4000 | 4000 |

| Clamping pressure/roller at 15 bar | daN | 250 | 250 | 400 | 400 | 600 | 880 | 880 |

| Centering accuracy over entire clamping range | mm | 0.04 | 0.04 | 0.05 | 0.06 | 0.06 | 0.08 | 0.08 |

| Repeatability | mm | 0.0007 | 0.0007 | 0.0007 | 0.01 | 0.01 | 0.02 | 0.02 |

| Max peripheral speed | m/min | 800 | 800 | 720 | 650 | 525 | 570 | 570 |

| Approx weight | kg | 53 | 53 | 115 | 190 | 500 | 580 | 650 |