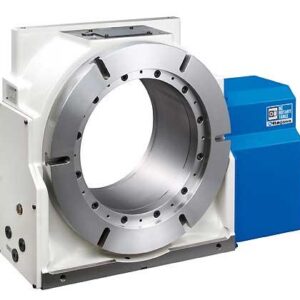

TUX・TUS series

Top motor type

Suitable for 5 axis machining with horizontal machining centre

TUX・TUS series

- High performance range suitable for 5th axis machining on horizontal machining centres

- High rigidity for heavy cutting

- High accuracy

- Top mounted motor position allows optimal machining area for horizontal 5 axis machining.

- Air-hydraulic booster provides high clamping torque

- Air-hydraulic booster or direct hydraulic clamping options available

- Rotary joint options available

- Rotary scale can be fitted to further increase accuracy.

*CE correspondence

Product Specifications

| Model | TUX200 | TUX250 | TUX320 | ||

|---|---|---|---|---|---|

| Table Diameter (mm) | ø200 | ø250 | ø320 | ||

| Centre Hole Diameter (mm) | ø75H7 | ø105H7 | ø130H7 | ||

| Through Hole Diameter (mm) | ø52 | ø78 | ø110 | ||

| Centre Height (mm) | 140 | 180 | 225 | ||

| Clamping Method | Air-hydraulic / Hydraulic | Air-hydraulic / Hydraulic | Air-hydraulic / Hydraulic | ||

| Clamping Torque (N・m) (at pneumatic 0.45MPa /hydraulic 3.5MPa) | 600 | 1100 | 2600 | ||

| Motor Axis Reduced Inertia (kg・m2) | 0.00055 | 0.00068 | 0.001 | ||

| Servomotor (for Fanuc spec.) | αiF 4/5000-B | αiF 4/5000-B | αiF 8/3000-B | ||

| Total Reduction Ratio | 1/90 | 1/90 | 1/120 | ||

| Max. Rotation Speed (min-1) | 33.3 (at motor 3000min-1) | 33.3 (at motor 3000min-1) | 25 (at motor 3000min-1) | ||

| Allowable Work Inertia (kg・m2) | 0.50 (1.00) note) | 0.98 (1.96) note) | 2.24 (4.48) note) | ||

| Indexing Accuracy (sec) | 20 | 20 | 20 | ||

| Repeatability (sec) | 4 | 4 | 4 | ||

| Mass of Product (kg) | 80 | 142 | 200 | ||

| Allowable Load | Vertical (kg) | 100 (200) note) | 125 (250) note) | 180 (360) note) | |

| Manual Tailstock (as an option) | TS200RN | TS250RN | TS320RN | ||

| Tail Spindle (as an option) | MSR142A/TSR142A | MSR181A/TSR181A | TSR181A45 | ||

| Rotary Joint (as an option) | RJ40H20V02 Hydraulic/Pneumatic 4 ports | RJ70H25V01 Hydraulic/Pneumatic 6 ports | RJ70H32V01 Hydraulic/Pneumatic 6 ports | ||

| Outline Drawing | Kitagawa own controller spec. | 2D |  |  | - |

|  | - | |||

|  | - | |||

|  | - | |||

| 3D |  |  |  | ||

|  |  | |||

| 4th axis spec. (Fanuc spec.) | 3D |  |  |  | |

|  |  | |||

| Option Outline Drawing | Tailstock Tail Spindle | ||||

Note) The values in ( ) are for using TS and TSR.

| Model | TUS400 | |||

|---|---|---|---|---|

| Table Diameter (mm) | ø320 | |||

| Face plate (Option) | ø400 with T-slots | |||

| Centre Hole Diameter (mm) | ø190H7 | |||

| Through Hole Diameter (mm) | ø154 | |||

| Centre Height (mm) | 255 | |||

| Clamping Method | Hydraulic | |||

| Clamping Torque (N・m) (at hydraulic 3.5MPa) | 7000 | |||

| Motor Axis Reduced Inertia (kg・m2) | 0.0065 | |||

| Servomotor (for Fanuc spec.) | αiF 12/4000-B αiF 22/3000-B | |||

| Total Reduction Ratio | 1/90 | |||

| Max. Rotation Speed (min-1) | 22.2 (at motor 2000min-1) | |||

| Allowable Work Inertia (kg・m2) | 5.00 (10.00) Note 2) | |||

| Indexing Accuracy (sec) | 20 | |||

| Repeatability (sec) | 4 | |||

| Mass of Product (kg) | 300 | |||

| Allowable Load | Vertical (kg) | 250 (500) Note 2) | ||

| Manual Tailstock (as an option) | TS400RN | |||

| Tail Spindle (as an option) | Order Production | |||

| Rotary Joint (as an option) | 7MPa 6 ports 7MPa 7 ports (Hyd./Pneu. 6+1 Note 1) ) 7MPa 8 ports 25MPa 11 ports (Hyd./Pneu. 10+1 Note 1)) 7MPa 13 ports (Hyd./Pneu. 12+1 Note 1)) | Used with MP scale 7MPa 6 ports 7MPa 8 ports | ||

| Used with rotary encoder 7MPa 6 ports | ||||

| Outline drawing | Kitagawa own controler spec. | 2D |  | |

| ||||

| ||||

| ||||

| 3D |  | |||

| ||||

| 4th axix (Fanuc spec.) | Motor case vertical type | Motor case horizontal type | ||

| 2D |  |  | ||

|  | |||

|  | |||

|  | |||

| 3D |  |  | ||

|  | |||

| 17-port rotary joint Outline drawing (Option) |  | |||

| ||||

| Outline drawing of option | Tail stock | |||

Note 1) The (+1) port of rotary joints is a multi-purpose hole for pneumatic port, high-pressure coolant, work seating detection sensor, etc. Please tell our sales staff the purpose in advance.

Note 2) The values in ( ) are for using TS and TSR.