Reach New Levels of Productivity

While the Kitagawa brand is globally recognized for its world-class workholding solutions, Kitagawa-NorthTech, Inc. is evolving years of machining and engineering experience into a new realm by launching a business consultancy group quite unlike its workholding heritage. This entity will engage the leadership of North America’s manufactures who are committed to the growth and profitability of their respective organizations.

Though each engagement must be viewed on its own merits, and the areas needing to be explored are well defined, the goal is always the same: Deliver Profitable Growth to the Client.

Productivity Programs

It is important for manufacturers to continue improving efficiency and productivity in order to maintain high levels of competitiveness in a continually evolving market. Our Productivity Programs are specially developed to help manufacturers refine operational processes through strategic consulting, diagnosis, action planning and implementation assistance, training and measurable growth. Our team will also provide the tools for customers to successfully identify future productivity restrictions and how to counter in order to stabilize and grow throughput.

Our Productivity Programs cater to a wide variety of machine shops, ranging from ultra-low volume production to ultra-high volume production, various industries and manufacturing specializations. We couple comprehensive improvement strategies with relevant training and reinforcement to generate optimum results.

Manufacturing Groups

Turning | Milling | Grinding | Handling | Heat Treat | Forging | Coating

Our goal is to work directly with management, engineering and shop person

![]()

nel to reach new levels of throughput by identifying ways to increase capacity, and reduce the chance of additional costs. The Productivity Programs include two core services: Process Optimization and Training Services.

Process Optimization

Mentor. Facilitate. Implement.

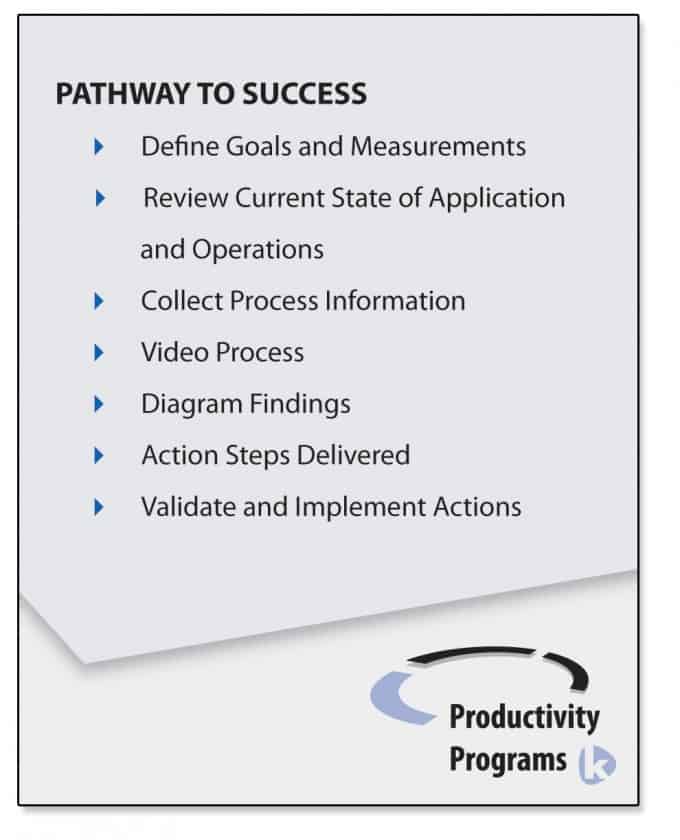

Process Optimization involves strategic consultation generated around shop floor activities, machines, materials and other methods and tools utilized for specific machining activities. Through a diagnostic approach, we work with the client to identify opportunities and formulate a Pathway to Success.

Optimization results will help solve a wide range of challenges experienced in machine shops, depending on the size and needs of the operation.

Operations

- Improve production rates / work flow

- Capacity liberation (latent capacity)

- Resolve scheduling issues and on-time rates

- Project based scheduling systems

- Reduce cycle times

- Reduce scrap

- Set-up reduction

- Reduce planned and unplanned downtime

Business Planning

- Bottom line profit growth

- Capacity planning

- CAPEX investment

- Expense reduction

Training Services

Training is essential to upholding optimization results and maintaining new practices for continued growth and profitability. Our training service is designed to help our customers maximize the longevity and usefulness of our products and programs. We will come to the facility and train as many people as desired. Training will be tailored to the operation’s needs to ensure maximum benefit for all who attend. Some of the topics covered include, installation, maintenance, safety and proper use.

As part of our ongoing mission to help our customer’s keep their workholding performing and minimize downtime, we also offer a preventative maintenance program. We can set up routine visits from our maintenance personnel to perform preventative maintenance at their facility. Our technicians will perform scheduled maintenance, tear down, inspect, clean and reassemble on any of our chucks the customer wants to have serviced. In addition, we can offer a full analysis of two and three jaw chuck grip forces. Using our wireless grip force meter we can determine whether or not a chuck is performing to specifications both dynamically and at rest. These services can greatly reduce downtime and improves the performance and longevity of our workholding systems.