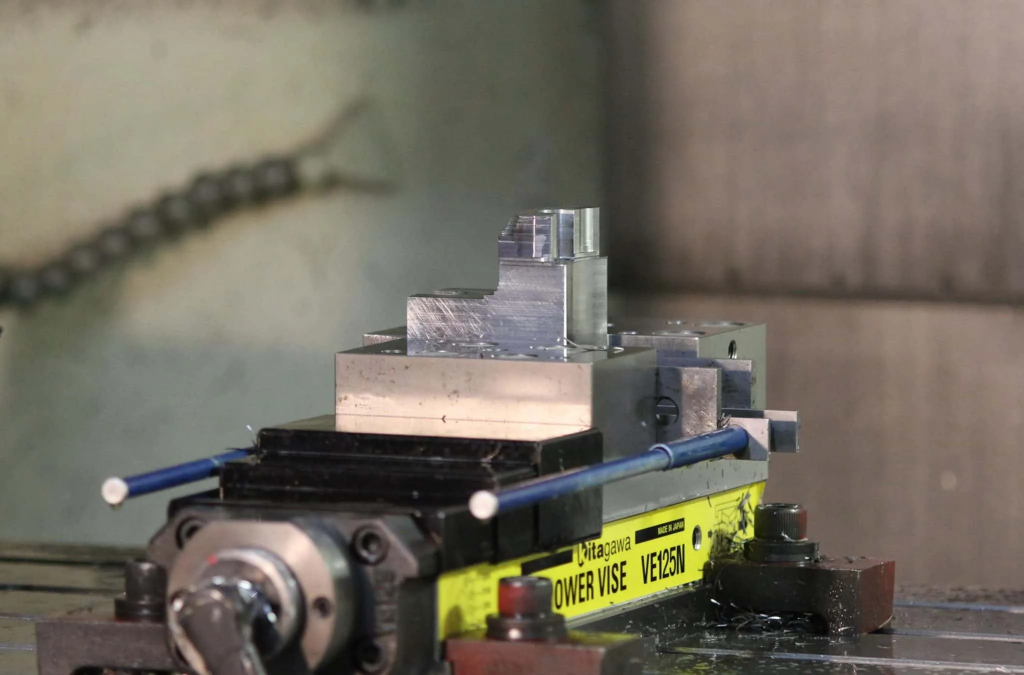

Comprehensive Workholding Systems Testing Before We Ship

No workholding system or fixture leaves our facility until they are fully tested on a test rig by an experienced engineer or technician. The assembly undergoes a series of rigorous quality control tests to ensure the workholding product meets exact project specifications. Rest assured, all tests are documented and kept on file at Kitagawa for future reference.

Extensive Inspection Processes Utilizing the Latest Metrology Equipment

Every workholding assembly is fully inspected and documented before it proceeds to final testing area. We utilize the latest metrology equipment to verify tolerances and measurements. This equipment includes Coordinate Measuring Machines (CMMs), Optical Comparators and Micrometers for our extensive inspection process.

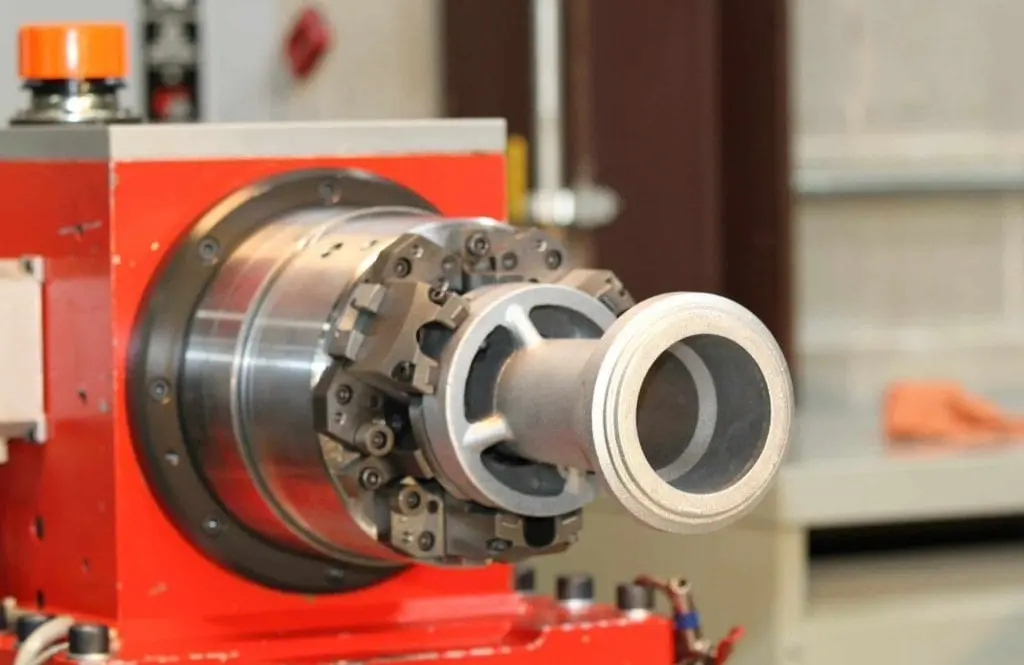

In-House Manufacturing for Advanced & Engineered Workholding

Our philosophy is to manage, control and provide as many manufacturing processes in-house to best serve our customers’ parts production requirements. In pursuit of this endeavor, we have turnkey in house manufacturing services at our North American headquarters in Schaumburg, IL. We offer custom design, engineering, manufacturing, inspection and testing of all engineered workholding and fixtures. By doing so, we maintain the lowest possible production costs, decrease product development times greatly and maximize quality for our customers.