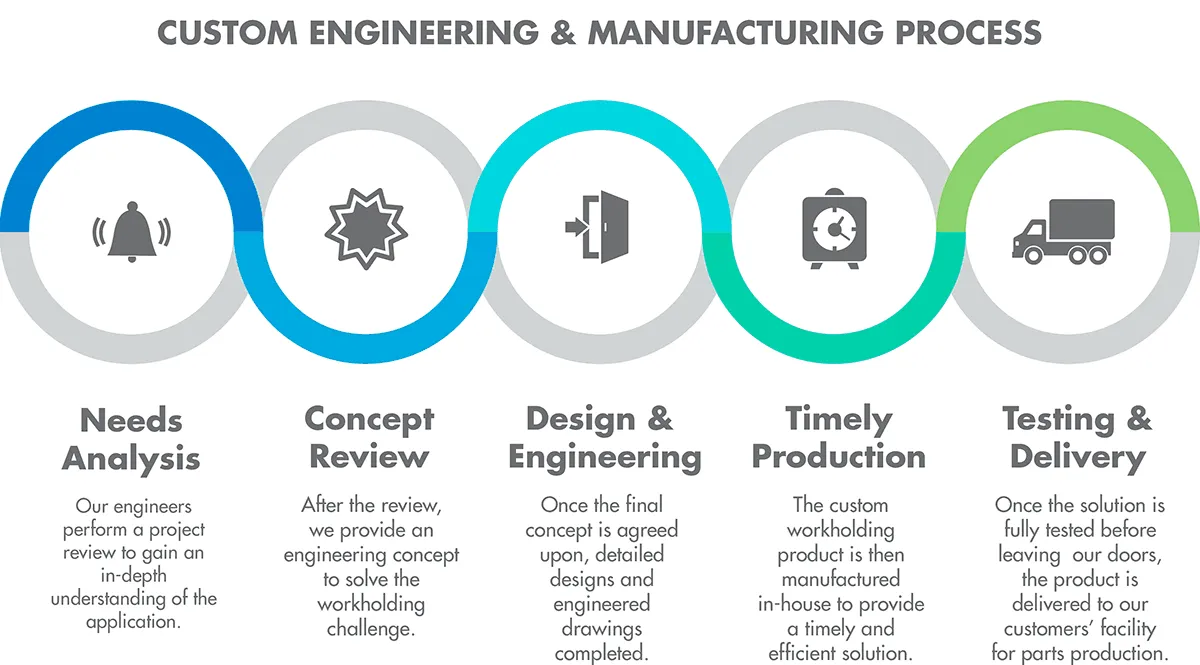

In addition to a broad range of standard, advanced power chucks, cylinders and accessories, Kitagawa NorthTech also offers in-house, applications engineering, custom engineered Workholding and productivity enhancement programs.

Our philosophy is to understand our customers’ needs thoroughly, and then design and manufacture a workholding system that is the “best solution” for their application. This solution can range from a modified chuck to a fully engineered, manufactured and tested workholding system that solves a part specific machining problem.

The Productivity Team is Dedicated to Solving Parts Machining Challenges

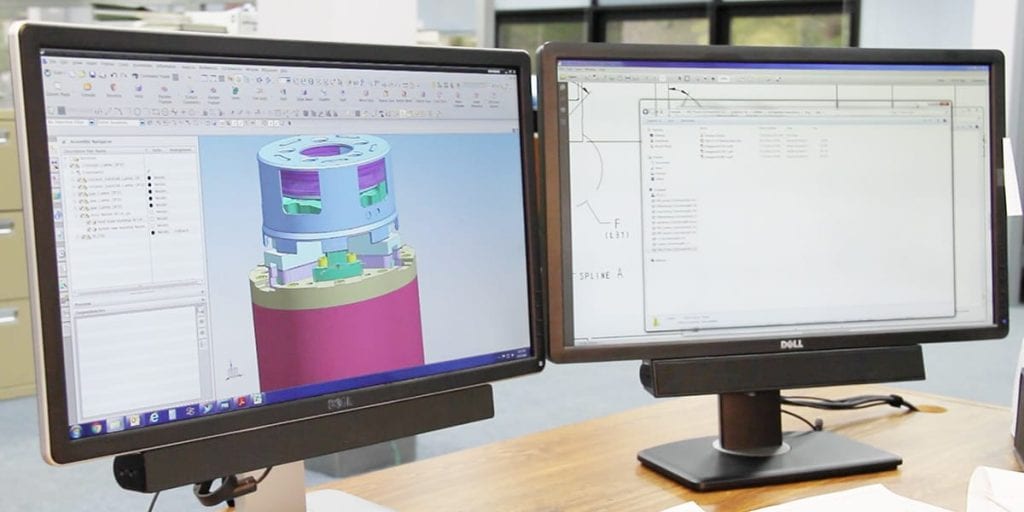

The Productivity Team consists of a team of trained and experienced mechanical engineers, manufacturing engineers and project managers. Their sole focus is to design, engineer and manufacture machining and Workholding solutions for customers. The P Team works as quickly, and as efficiently as possible to meet customers’ desired production timeline requirements.

Engineering Commitment:

- In-depth Customer Consultation

- Extensive Development & Review

- Total Project Management

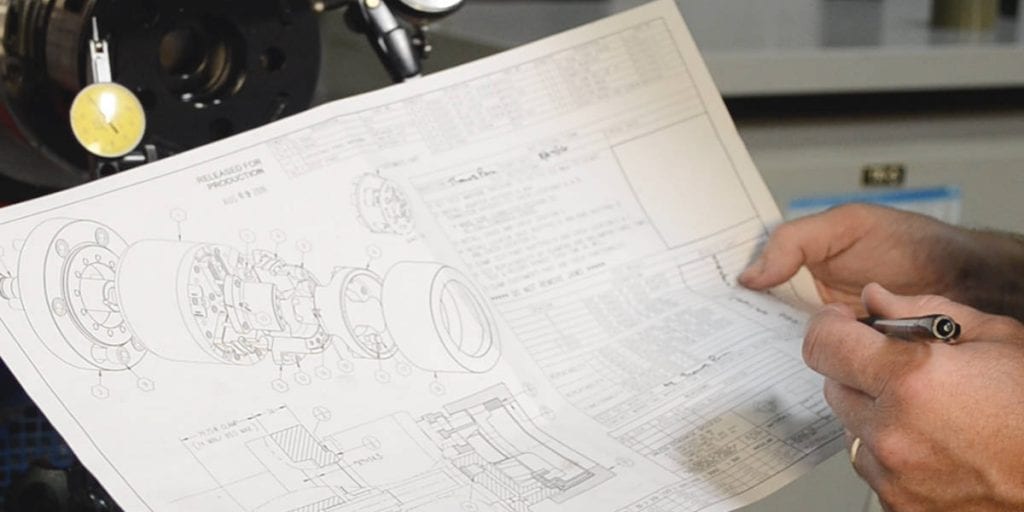

- Comprehensive Documentation

- Guaranteed Results

- Customer Satisfaction

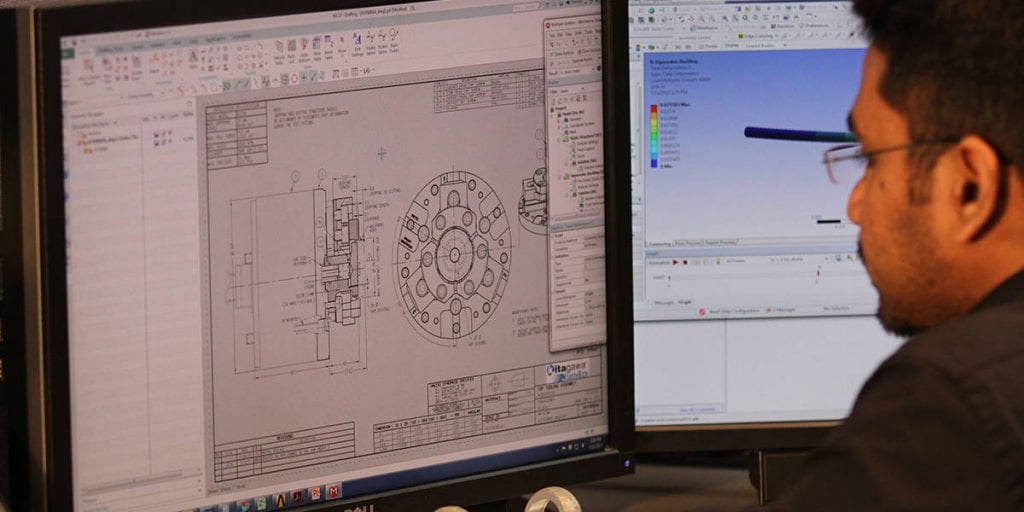

Analysis Includes:

- Stress

- Fatigue

- Dynamic Balancing

- Center of Mass

- Centrifugal Forces

- Deformation

Total Satisfaction Ensured:

- Designed and Manufactured to Exact Specifications

- 100% Tested & Proven Before Leaving Our Doors

- Complete Documentation

- On Time Delivery

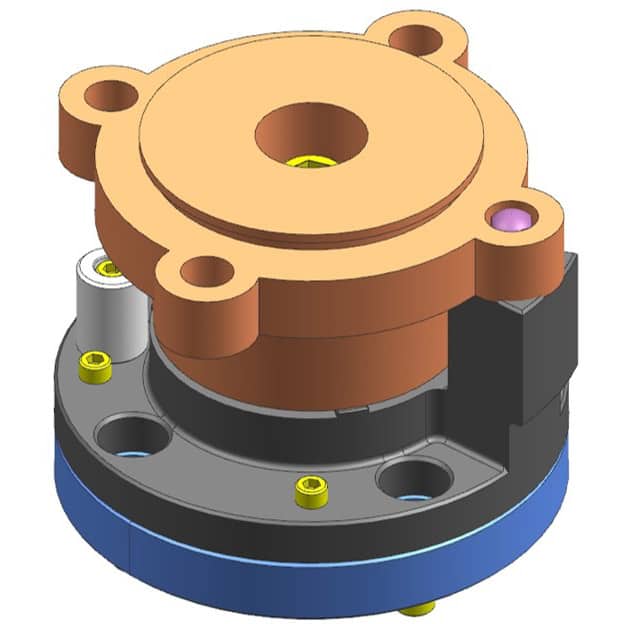

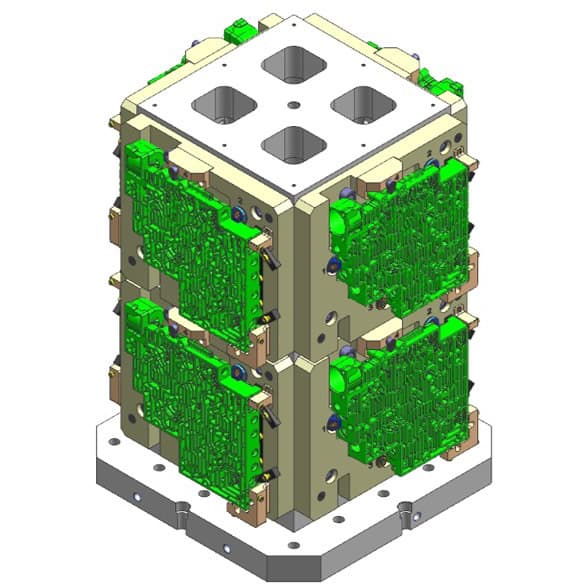

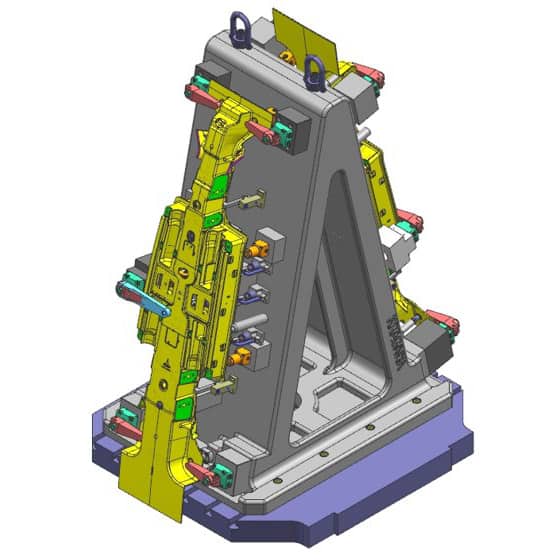

Extensive Custom Engineered Rotational & Stationary Solutions

Our Productivity Team has expertise designing, engineering and manufacturing an extensive range of workholding and tooling for turning or prismatic applications. Simple or tough, let the Kitagawa Productivity Team solve your machining problems.